僅供個人參考(kǎo)

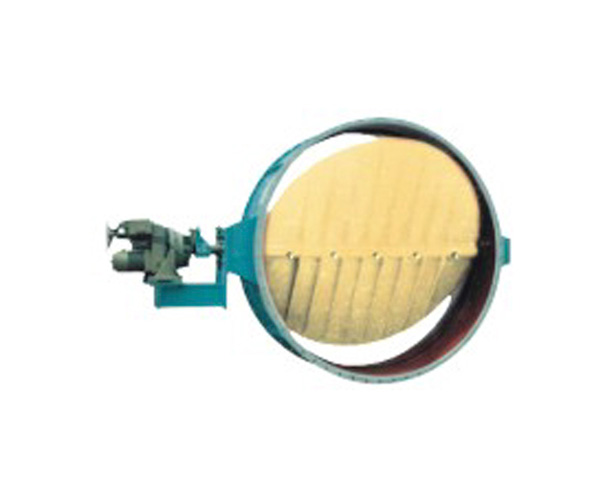

直聯式自(zì)動調節蝶(dié)閥(fá),普遍适(shì)用于建材、玻璃、礦山(shān)、電力、輕工、造紙等行(háng)業的(de)通(tōng)風(fēng)、環保工程(chéng)等管道系(xì)統中(zhōng)。對管道中(zhōng)氣體介質按(àn)不同控制信(xìn)号調節流(liú)量大小(xiǎo)和切斷。

this valve is widely used in the pipe system such as venting and environment protection in building material, glass, mining, power, light industry and papermaking departments. it can change the flow and cut off gas medium in the pipe by the different control signal.

結構特點:

structure characteristic:

直聯(lián)式自動調(diào)節蝶(dié)閥,采用(yòng)優(yōu)質鋼(gāng)材焊(hàn)接。具有結(jié)構合(hé)理(lǐ)、耐磨損(sǔn)、流阻損失(shī)小、操(cāo)作靈活、指示方位明确(què)、維護方(fāng)便、使(shǐ)用壽(shòu)命長等優點(diǎn)。可實現任意(yì)角度安裝(zhuāng)。配用dkj、zkj、伯納(nà)德等(děng)電動(dòng)執行器及(jí)有關(guān)配件(jiàn),可實現手動、自動無(wú)幹擾切換(huàn)、微(wēi)機程控、自(zì)動控制(zhì)或中(zhōng)央集中控(kòng)制,是(shì)實(shí)現自動(dòng)化(huà)控(kòng)制(zhì)操作、調(diào)節流(liú)量的理想設備。

the valve is welded in fine steel, having the features of compact structure, endurance, little in the lost of flow resistance, definite direction, easy to maintenance and long life. it can be installed at any angle. the valve is used with dkj, zkj, bernard electric actuator and other accessory to form a complete set to realize manual and automatic exchange without interference, micro-computer long-range control, automatic control or center concentrating control. it is the ideal equipment of realizing operation of automatic control and adjusting flow.

性能(néng)參數(shù):

performance parameter:

公稱壓力(lì) nominal pressure | 介質流速(sù) medium velocity | 洩漏率 leakage ratio | 适用溫度 suitable temperature | 适(shì)用介(jiè)質 suitable medium | |

0.05mpa | ≤25m/s | ≤1% | c | mn | 空氣、煙(yān)氣、粉塵氣體等 air, smoke , gas with powder etc |

dkjw---0.5c mn外形(xíng)連接尺(chǐ)寸:

appearance joint dimensions:

dn | d | d1 | b | b | n-d | e | e1 | l | 執行器參(cān)數 parameter |

100 | 180 | 145 | 180 | 8 | 4-Φ12 | 955 | 600 | 450 | dkj-210 t:100n·m p:0.025kw |

200 | 280 | 245 | 180 | 8 | 8-Φ12 | 1065 | 650 | 450 | |

300 | 400 | 355 | 180 | 8 | 12-Φ12 | 1185 | 725 | 450 | |

400 | 500 | 455 | 200 | 10 | 16-Φ14 | 1485 | 815 | 500 | dkj-310 t:250n·m p:0.065kw |

500 | 600 | 555 | 200 | 10 | 20-Φ14 | 1586 | 915 | 500 | |

600 | 700 | 655 | 200 | 10 | 20-Φ14 | 1696 | 1015 | 500 | |

700 | 800 | 755 | 220 | 10 | 20-Φ14 | 1880 | 1125 | 600 | dkj-410 t:600n·m p:0.16kw |

800 | 900 | 855 | 220 | 10 | 24-Φ14 | 1995 | 1175 | 600 | |

900 | 1000 | 955 | 220 | 10 | 24-Φ14 | 2095 | 1475 | 600 | |

1000 | 1130 | 1070 | 260 | 12 | 28-Φ18 | 2355 | 1525 | 620 | dkj-510 t:1600n·m p:0.4kw |

1100 | 1230 | 1170 | 260 | 12 | 28-Φ18 | 2455 | 1575 | 620 | |

1200 | 1330 | 1270 | 260 | 12 | 28-Φ18 | 2555 | 1625 | 620 | |

1300 | 1430 | 1370 | 300 | 12 | 32-Φ18 | 2655 | 1725 | 620 | |

1400 | 1530 | 1470 | 300 | 12 | 36-Φ18 | 2755 | 1775 | 620 | |

1500 | 1630 | 1570 | 300 | 12 | 36-Φ18 | 2870 | 1845 | 620 | |

1600 | 1730 | 1670 | 300 | 12 | 40-Φ18 | 2970 | 1895 | 620 | |

1700 | 1830 | 1770 | 340 | 16 | 40-Φ18 | 3210 | 1945 | 650 | dkj-610a t:2500n·m p:0.65kw |

1800 | 1930 | 1870 | 340 | 16 | 44-Φ18 | 3310 | 1995 | 650 | |

1900 | 2030 | 1970 | 340 | 16 | 44-Φ18 | 3410 | 2045 | 650 | |

2000 | 2130 | 2070 | 340 | 16 | 48-Φ22 | 3510 | 2095 | 650 | |

2100 | 2230 | 2170 | 340 | 16 | 48-Φ22 | 3625 | 2145 | 650 | |

2200 | 2330 | 2270 | 340 | 16 | 48-Φ22 | 3725 | 2195 | 650 | |

2300 | 2430 | 2370 | 380 | 16 | 48-Φ22 | 3935 | 2245 | 650 | dkj-610 t:4000n·m p:1.0kw |

2400 | 2530 | 2470 | 380 | 16 | 48-Φ22 | 4035 | 2295 | 650 | |

2500 | 2630 | 2570 | 380 | 16 | 52-Φ22 | 4135 | 2345 | 650 | |

2600 | 2730 | 2670 | 380 | 16 | 52-Φ22 | 4235 | 2395 | 650 | |

2700 | 2830 | 2770 | 420 | 20 | 56-Φ22 | 4340 | 2550 | 700 | dkj-710 t:6000n·m p:1.0kw |

2800 | 2930 | 2870 | 420 | 20 | 60-Φ22 | 4440 | 2600 | 700 | |

2900 | 3030 | 2970 | 420 | 20 | 60-Φ22 | 4540 | 2650 | 700 | |

3000 | 3130 | 3070 | 420 | 20 | 60-Φ22 | 4640 | 2700 | 700 |

湖北祥盛迪亞集團有限公司 版(bǎn)權所有(yǒu) 荊州(zhōu)百捷 技術(shù)支持(chí)

地址:荊州市沙(shā)市區(qū)十号(hào)路 咨詢熱(rè)線:0716-8878286